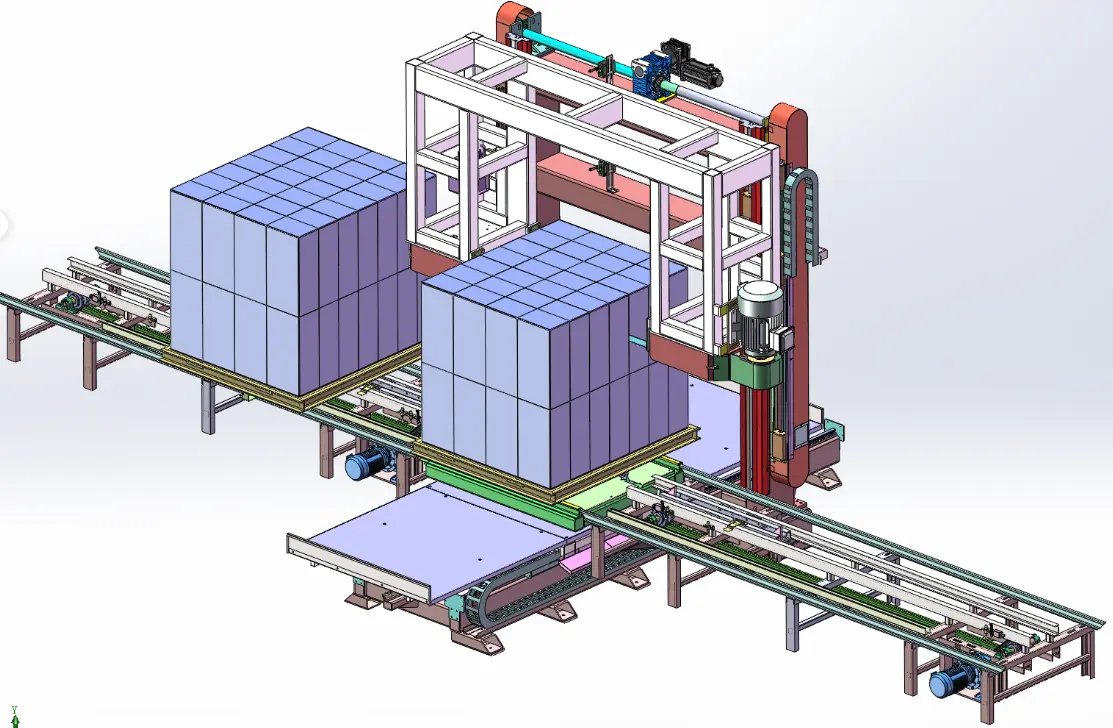

The eighth generation of lightweight block cutting machine is officially launched, and the system level upgrade helps efficient continuous production.

Recently, our company officially launched the eighth generation of lightweight block cutting machine. This upgrade is a system-level technology iteration, around the lifting speed, cutting speed and line speed for a comprehensive optimization, the overall operating efficiency of the equipment compared with the previous generation increased by more than 2 times, to further meet the demand for high-intensity, continuous production.

I. Core upgrade content

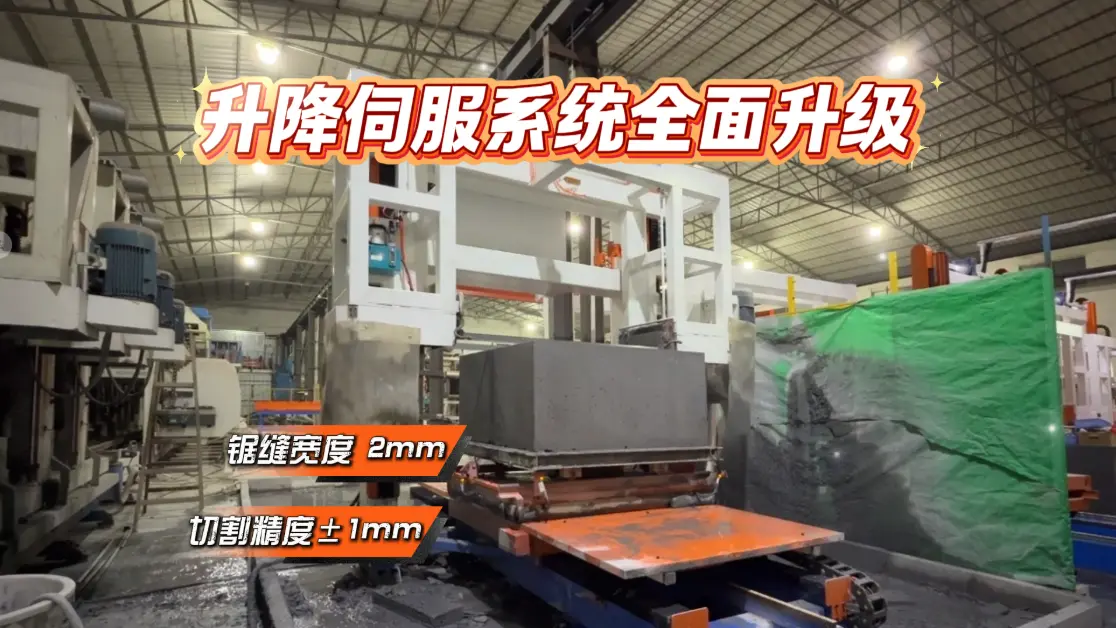

1. Comprehensive upgrade of elevation servo system

The eighth generation cutting machine adopts upgraded elevation servo system, which significantly improves the control response speed and can adapt to high-frequency and high-load cutting conditions. Simultaneously, the structure of the saw frame is strengthened and the overall rigidity is upgraded to achieve stability and reliability under long-term continuous operation. Compared with the previous generation, the lifting response and positioning efficiency have been improved by about 3 times.

2. Increased cutting line speed

By upgrading and optimizing the pulley system, the machine can run smoothly at a maximum speed ratio of 80, which significantly improves the cutting line speed and increases the overall cutting efficiency by more than 2 times compared with the previous generation, further releasing the production capacity while ensuring the stability.

3. Enhanced adjustment and adaptability

In response to the needs of users who upgrade and replace cutting saws, the eighth generation of cutting machines has strengthened the ability to adapt to different mold sizes and cutting specifications. The machine supports multi-directional compensation fine-tuning in front, back, left and right, which can still realize stable and accurate cutting even in the case of slight deformation of the embryo body.

Second, after upgrading performance index

-

Cutting precision: ±1mm

-

Sawing width: 2mm

Before officially leaving the factory, the equipment has completed a total of 6 machine tests, including 4 hours of empty machine fatigue test. After the completion of the test into the actual cutting stage, in the product strength of 1.8-2.2 MPa conditions for cutting verification:

-

Cutting time for single embryo: 3 minutes and 35 seconds

-

Cutting time for double embryo stacking: 5 minutes and 30 seconds.

Each index runs stably and meets the requirements of large-scale and continuous production.

Third, upgrade purpose

The company has always insisted on engineering practice as the guide, and continued to carry out technical iteration and system optimization of the core equipment. The launch of the eighth generation of lightweight block cutting machine is a milestone achievement of our long-term accumulation and continuous research and development in the field of cutting system.

In the future, we will continue to provide high-quality, high-precision, cost-effective cutting saws and complete line of equipment solutions for global lightweight wall material manufacturers, steadily promote the development of band saw cutting technology, and continue to shape the leading brand of band saw cutting.