Self-insulation block equipment is good for dry cutting or wet cutting The company developed a new 360-degree rotary cutting saw

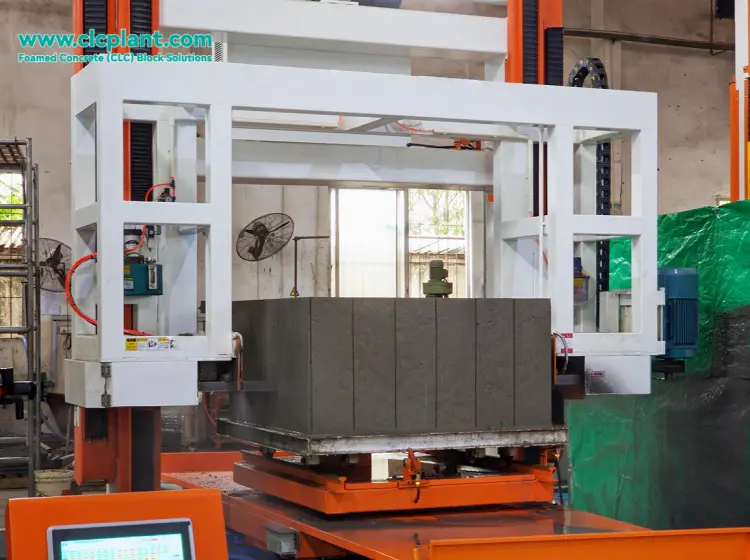

For the current wet cutting problems, the company's new research and development of a set of 360-degree rotary cutting saw equipment using high-strength alloy band saws, cutting machine selection in the product strength is suitable for when the product for the overall six-sided cutting, cutting shape neat, angular and can product size, the softness and hardness of the concrete billet of the requirements of the more flexible, extend the time period can be cut, the cutting time can be more controllable. This set of 360-degree rotary cutting saw adopts through the cutting process to take into account the advantages of lifting mold cutting and dry cutting, simple and compact structure, easy maintenance, small footprint, cutting with less people. With the advantage of low cost and no pollution compared to other types of cutting machines on the market has a very obvious advantage. The company's 360-degree rotary cutting saw is the use of independent patented technology of fully automatic cutting machine, regardless of the full-automatic level of the cutting machine, or cutting process level is unique, the production capacity of the block equipment and yield effect of the enhancement of the obvious, product quality, advantages and supporting the level of significantly improved.

Dry cutting and wet cutting is the block equipment production process of the two mainstream cutting process, today for EPS self-insulated block production to analyze the importance of cutting machine on the production. Dry cutting method also known as active cutting, wet cutting method called passive cutting.

Dry cutting method, that is, after the block molding, after maintenance (natural maintenance or artificial maintenance), in the product strength to a certain extent and then cut, known as active cutting. Its advantage is not subject to time constraints, can be arbitrarily arranged cutting, can be operated in a large space. Wet cutting method, that is, after the block is molded, it is cut when the strength is low, which is called passive cutting. Its advantage is that the appearance of the block is very good, there is no loss, and the side skin can be recycled and reused immediately after cutting. The disadvantage of wet cutting of self-insulated blocks is that it is necessary to master the cutting time, early blocks will be deformed, late cutting is not moving, if there is no hard cutting to match, then the whole box of blocks becomes to cause waste. Sometimes because of the temperature and raw material differences, after the production of blocks will be produced at the same time as the first to reach the strength, so that we simply do not have time to cut. And if you find that the technology is not good after cutting will cause back slurry. So that the block again adhesion, both affect the appearance and labor-intensive to laboriously resistant to open. In addition, wet cutting is generally operated by steel wire or rope saw, because the steel wire and rope saw, no matter how taut, the force will be curved, resulting in cutting not to the bottom.

For cutting noise and pollution problems, the current choice of wet addition process is better. Cutting machine has a great influence on the products of self-insulation block equipment, which is the key equipment in the whole set of production line. The quality of the cutting machine directly determines the quality of the finished block, and also has a great impact on the size of the output.