How to open a small aerated block factory

First, raw material selection and utilization

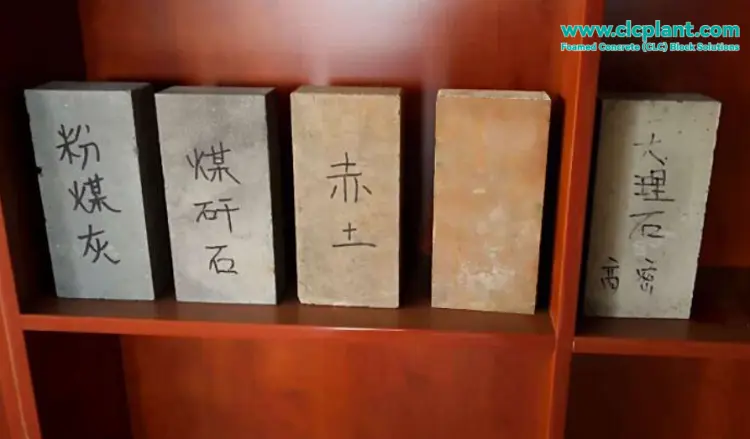

The first task of starting an aerated block plant is to ensure that the supply of raw materials is stable and the cost is controllable. It is recommended to choose raw materials that can be locally sourced and inexpensive, such as:

-

Sand

-

Fly ash

-

Powder gangue

-

Slag

-

Tailings and other industrial wastes

These materials are not only from a wide range of sources, low prices, but also to achieve resource utilization of industrial waste, in line with the requirements of the circular economy and environmental policy.

Second, understand the market prospects and policy support

The state in the "13th Five-Year Plan" clearly put forward to promote energy conservation and emission reduction and the development of circular economy, and strongly support the research and development and application of new wall materials. Specific policies include:

-

Tax reductions, tax exemptions and other financial support;

-

Capital subsidies or project funding;

-

Mandatory standards for building energy efficiency, requiring new buildings to use energy-saving and environmentally friendly wall materials.

At present, the utilization rate of new wall materials has increased from 35% to 65%, and the market demand continues to expand, with a bright future for products such as aerated blocks, lightweight bricks, and self-insulated blocks.

Third, equipment selection and technical inspection

Selecting reliable equipment suppliers is the key to the success of the project. It is recommended that investors:

-

Field inspection of equipment manufacturers to confirm whether they have a research and development base and production workshop;

-

Understand the source of equipment technology, the degree of automation and process maturity;

-

Refer to successful cases to assess the stability of the equipment and the quality of after-sales service.

Our aerated block equipment adopts advanced technology from Germany to create fully automatic production line, which has the advantages of small investment, high finished product rate, low cost, large profit margin, etc. It is the preferred partner of small aerated block factory.

Investment amount and project planning

The investment scale of small aerated block factory can be chosen flexibly according to your own financial strength and local market. Need to focus on the following aspects:

-

Scale of the plant: determine the land area according to the output;

-

Raw material reserve: to ensure a smooth supply channel;

-

Water, electricity and labor: estimating daily operating costs;

-

Environmental protection approval: to meet local environmental protection requirements;

-

Business license and production permit: for relevant qualification procedures.

It is recommended that the initial investment of several hundred thousand to one million dollars, the specific amount should be combined with the selection of equipment and plant construction to assess the situation.

Fifth, the production process and technology selection

Aerated block production process mainly includes cement pouring, cutting and maintenance of three links. There are differences in the process technology of different manufacturers, which directly affects product quality, yield and cost. Compared with the traditional process, the new generation technology has obvious advantages in terms of energy saving, automation degree and finished product rate.

The selection of equipment should focus on:

-

Whether to realize automation control;

-

Cutting precision and finished product qualification rate;

-

Maintenance cycle and energy consumption level;

-

Whether to support a variety of raw material ratios and adaptability.

Sixth, environmental protection and social value

Aerated block equipment can make large use of industrial waste, to achieve "zero growth in resource consumption, zero emission of waste", not only to reduce production costs, but also conducive to environmental protection. Aerated block products with thermal insulation, heat insulation, lightweight, earthquake, fire, water, moisture, anti-electromagnetic wave and other excellent characteristics, widely used in various types of civil and public buildings, in line with the multifunctional needs of modern construction materials.

Starting a small aerated block factory is an entrepreneurial choice with good market prospects and policy support. Through rational planning, choose the right equipment, understand the policy, control costs, can completely open up a new world in the field of green building materials. If you are preparing to enter this industry, it is recommended that you make a site visit as early as possible, cooperate with equipment suppliers with mature technology, and lay a solid foundation for the smooth landing of the project.

Our company specializes in aerated block equipment R & D and manufacturing, to provide fully automated production line solutions, interested investors are welcome to contact us to get more details of the equipment and plant construction planning advice.