Zhejiang customer autoclaved aerated block equipment transformation ceramic block project

Project Name

Zhejiang customer autoclaved aerated block equipment transformation ceramic block project

Project Time

October 2024

Project Background

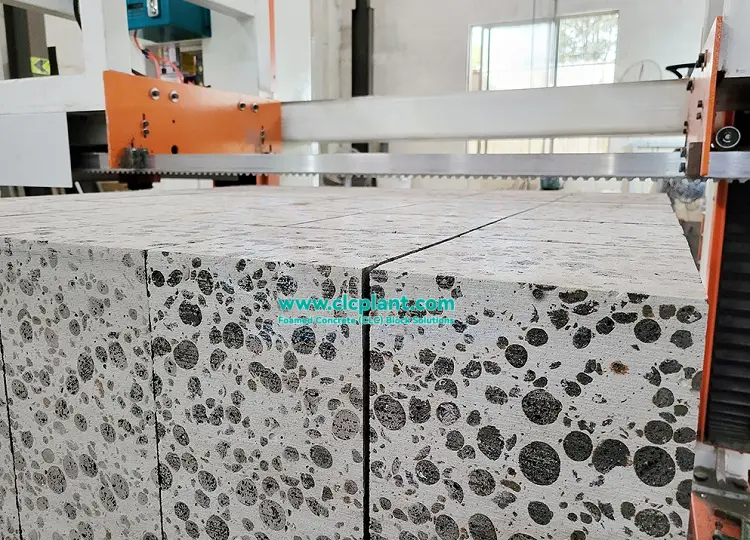

With the green transformation of the building materials industry and the diversification of market demand, ceramic blocks have gradually become an important choice for new wall materials due to its lightweight, high strength, thermal insulation and other performance advantages. Based on the market trend and production upgrading demand, the Zhejiang customer decided to transform the original autoclaved aerated block production line into a ceramic block production line to enhance product competitiveness and market adaptability.

Customer Needs

The customer wants to realize the following goals through technical transformation:

-

Transform the existing autoclaved aerated block equipment into ceramic granule block production line

-

Ensure that the equipment meets the requirements of ceramic block production process after transformation

-

Provide customized equipment solutions to adapt to the existing site conditions

-

Ensure stable performance of the equipment for quick start-up and long-term reliable operation.

-

Provide professional technical training to improve the operation and maintenance capability.

Cooperation process

Our company provides customers with full-process technical services:

-

Demand docking and program design: in-depth investigation of the customer's existing equipment and site conditions, and customized transformation program.

-

Equipment customization and manufacturing: play the professional advantages of the technical team, the use of advanced technology and strict quality management, customized ceramic block production equipment

-

Installation and commissioning: the professional team completes the installation and commissioning of the equipment efficiently on site to ensure the smooth operation of the production line.

-

Technical training: Organize special training to explain in detail the operation, maintenance and troubleshooting methods of the equipment, and improve the skills of the customer team.

Project Effect

The project successfully realized the expected goals:

-

Successful completion of production line modification and successful production of ceramic block products.

-

Stable operation of the equipment, production efficiency and product quality meet the design requirements.

-

The client's team mastered the operation and maintenance skills of the equipment to ensure long-term stable production.

-

Bringing significant economic benefits to the customer and supporting the enhancement of its market competitiveness.

-

This project has become an industry model for the transformation of autoclaved aerated block equipment into ceramic block production.